WHY THIS MATTERS IN BRIEF

- Particle accelerators are enormous beasts but being able to miniaturise them and put them onto chips will democratise the technology and open doors for new discoveries in energy, healthcare, materials and many more fields of science

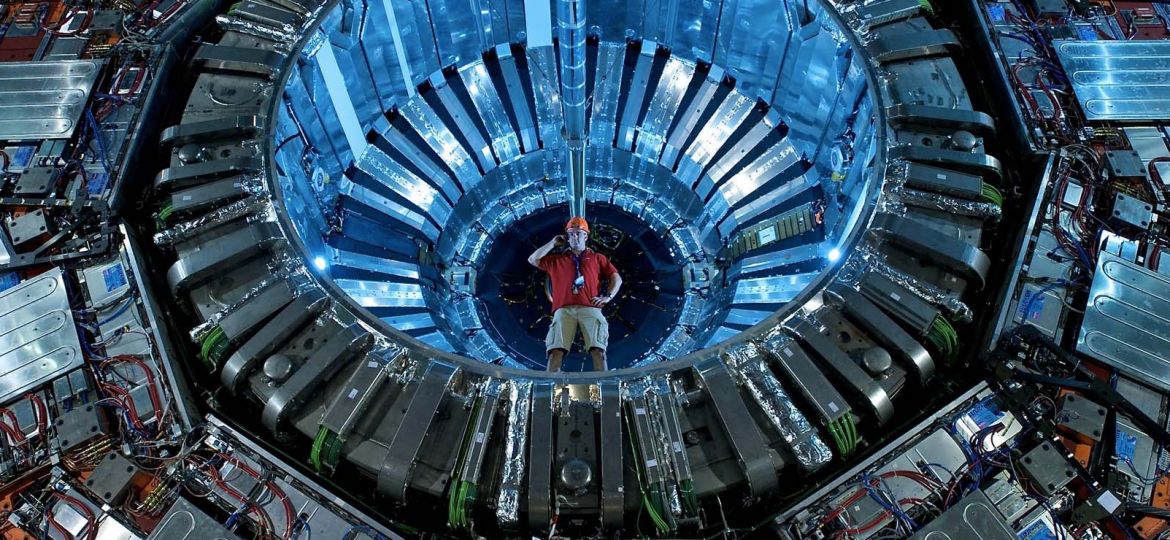

Sixteen months ago The Gordon and Betty Moore Foundation awarded US $13.5 million to a five year project involving an international collection of universities and national labs to start work on shrinking particle accelerators – those huge things, like the one at CERN, that occupy sites the size of a small town – so that they could fit on a chip.

The project, which is catchily dubbed “Accelerator on a Chip” could have a profound impact on both fundamental science and materials research, and medicine.

In short the teams involved want to use lasers, instead of microwaves that are used in most of today’s larger particle accelerators, and nanostructured silicon the size of a grain of rice to accelerate electrons at a rate 10 times higher than conventional technology can, and the resulting technology could potentially match the power of the America’s national particle accelerator at Stanford’s Linear Accelerator Center (SLAC), a 3.2 kilometer long linear accelerator behemoth, in as little as 30 meters.

That would be a paradigm shift in capability.

“The idea actually originates from the 1960s, shortly after the laser was first invented, in a paper by the University of Tokyo that proposed using a laser as a means to accelerate charged particles to high energy,” says Joel England, a fellow at the Advanced Accelerator Research Department at SLAC and the person leading the Accelerator-on-a-Chip project, “at the time, the technology didn’t really exist to actually realise it, but since then we’ve had the development of nanofabrication technology to make very tiny devices and solid state lasers which are now very efficient.”

England explains that the Accelerator-on-a-Chip project has already been able to harness these converging technologies of nanofabrication and solid state lasers and combine them to make a miniaturised particle accelerator.

Operationally the new miniaturised particle accelerator works using the same basic principles of its large scale cousins that use metallic, microwave cavities to speed up the electrons. But instead of drawing its power from microwaves, whose wavelengths are measured in centimeters, the team are using lasers which have wavelengths of micrometers – 10,000 times smaller .

“So it’s a big change in scale,” says England, “and it allows us to shrink down the size of the structure by that amount as well.”

Not only has the size of the structures been shrunk but also different types of materials are needed. Instead of using metal cavities, the miniaturised structures are fabricated from dielectrics, which are basically just a different type of glass that are optically transparent so you can you can get laser light to go through them.

When the nanostructures carved into the glass are designed correctly when light passes through them they generate an electric field that kicks charged particles as they pass by and accelerates them.

The key to getting the technology to work is the design of the nanostructures. Get the design right and you give the particles a kick and accelerate them, get it wrong and they mooch about and get stuck on the peaks of the nanostructure.

“In the future we want to bunch the particles to make very short little packets of particles that are spaced at exactly the right distance so that they will ride only on the laser lights peaks,” says England, “so you can think of it as like ocean waves, and you want your surfers to be positioned only on the peaks of the waves and not in the troughs so they move forwards.”

The practical benefits of shrinking a particle accelerator down to the size of chip are pretty self-evident. By making it chip scale leads to manufacturing costs being significantly less. It would also make it possible to produce hundreds or thousands of them very quickly. You can even imagine having a disposable accelerator so that when a part of it breaks, you plug in another chip.

There are enormous costs and size benefits too. For example, you could have portable versions of what are now large and heavy and cumbersome devices like medical linear accelerators, and while there are over 30,000 large particle accelerators dotted around the world the reality is there are still huge queues of people waiting to use them, and this could democratise the technology.

“In radiation therapy for cancer treatment medical linear accelerators weigh about 10,000 pounds and cost around $3 million,” says England, “so if you could make it with a microchip and have a very tiny device that’s portable, all you would need to do is plug a fiber laser into it to power it. This could lead to this therapy being used in a lot more settings and in areas of the world where there were cost restrictions on purchasing therapy devices like that.”

“One of the dreams is to make molecular movies and observe in real time how molecules interact and combine with each other, or something where you capture the state of a molecule at different times in its evolution,” says England.

England likens the ability to going from a camera where you take a picture once every few seconds to having a very high speed camera where you can capture the details of a water droplet landing on an insect.

England and his colleagues still have three and a half years left in this phase of the research, and if the initial results are any indication, we can expect that applications may not be too far off in the future.

So who knows, by 2025 you might have a miniature particle accelerator in your pocket, now the only question is what would you do with it? Make toast perhaps or cure cancer? The options are endless…