WHY THIS MATTERS IN BRIEF

3D printing will undoubtedly change how the world makes goods, but it’s still expensive and slow, now we’re seeing a slew of new technologies that are trying to speed up manufacturing and change the game.

Coming hot on the heels of another new 3D Printing technique, Holographic Printing, researchers at MIT have developed what they’re calling a “revolutionary new form of 3D printing” that can produce large objects, such as chairs, in a fraction of the time it would take to build something similar using traditional 3D printers. Called Rapid Liquid Printing, the new technology extrudes material from the nozzle of the printer into a vat of gelatinous liquid and it’s this that makes manufacturing products thousands of times faster.

“In the beginning we started with this question – could you print furniture in minutes?” said MIT lab director Skylar Tibbits, whose other projects also include 4D printing space stations that assemble themselves and printing futuristic materials, “and if you look at printing from that perspective it forces you to think about it in a completely different way.”

Rapid Liquid Printing In Action

The team’s aim was to tackle the three main challenges that they believe have prevented 3D printing’s widespread adoption in manufacturing so far, namely speed, scale and material properties.

“Most of the time we can only print centimetre scale structures, and for furniture, that’s means [3D printing] is still unfeasible,” said Tibbits, “and there are a couple of reasons why the properties aren’t so good. Nearly every 3D printing process utilises layers, and those layers degrade the structural property of the material compared to a consistent material all the way through.”

Rapid Liquid Printing works by letting the printers robotic nozzles “draw” freely in a 3D space that’s only constrained by the size of the tank, and the gel it draws in, which is similar to hair gel, suspends the extruded material so it doesn’t have to fight gravity or, unlike 3D printing, require a base plate to build upon.

The team’s experimented with a variety of printing materials so far including plastics, rubbers and polyurethanes with different properties, and in each case, two materials are mixed together in the nozzle and are chemically cured as they’re extruded. The material is then pushed out like toothpaste from a tube, so has better structural integrity than if it was laid down as a series of layers, which is essential if it needs to bear weight.

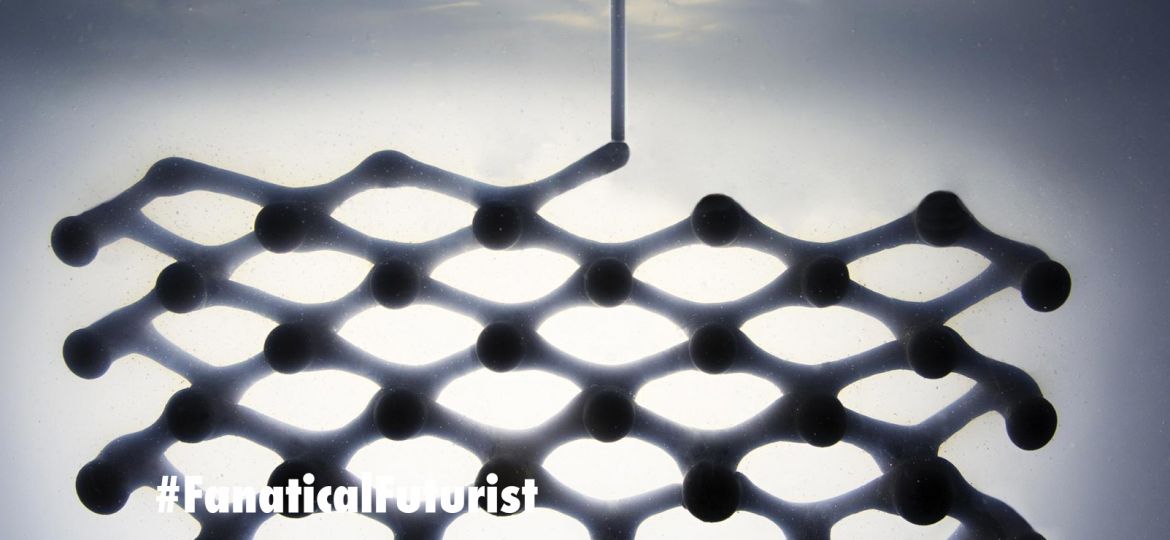

One of the first applications of Rapid Liquid Printing was a set of furniture that the team showed off at a conference in Miami last year, and collaborating with Swiss product designer Christophe Guberan, they also produced a set of items made up of printed latticed surfaces to demonstrate the potential of the technology. Meanwhile designer Yuka Hiyoshi from Steelcase, an American office furniture manufacturer who partnered with MIT during the project, used the process to create a table top that can be made to the exact size required by the customer, as part of a collection called Bassline.

Steelcase especially sees Rapid Liquid Printing as an important step forwards in helping them create tailored office furniture, while Tibbits believes the technology has wider potential such as applications in large scale manufacturing, including aerospace, automotive and architectural applications.