WHY THIS MATTERS IN BRIEF

A new development in material science opens the door for the development of more advanced Smart Clothing.

Many of today’s smart clothes, such as those from Adidas, Athos, Nike, Ralf Lauren and Under Armour rely on sensors, such as EMG sensors, woven into the fabric to communicate information back to a unit or device that can process and analyse it but now a new discovery paves the way for clothing to be integrated with more powerful “on board” computer circuits and chips which could open up new use cases – if, that is, the technology ever finds its way into a commercial application.

Academics in Hong Kong have used a computerised knitting machine to weave electrical circuits into clothing that can resist stretching, washing and even the impact of bullets. The team from the University’s Institute of Textiles and Clothing used copper coated in polyutherane to carry the current and then sewed these strands together with filaments of pre-stretched elastic yarn to create the finished garment which can then be integrated and augmented with a variety of chips and flexible circuits.

The details of their experiment were published in the journal Proceedings of the Royal Society A and it shows that the new fabric can tolerate a 20% deformation around 1 million times before it begins to fail. Meanwhile though – when it was tested in a domestic washing machine at 40°C, followed by tumble drying at 75°C after 30 such washing and drying cycles – 20% of samples showed some degradation in performance so there is evidently some way to go still before the prototype is production ready.

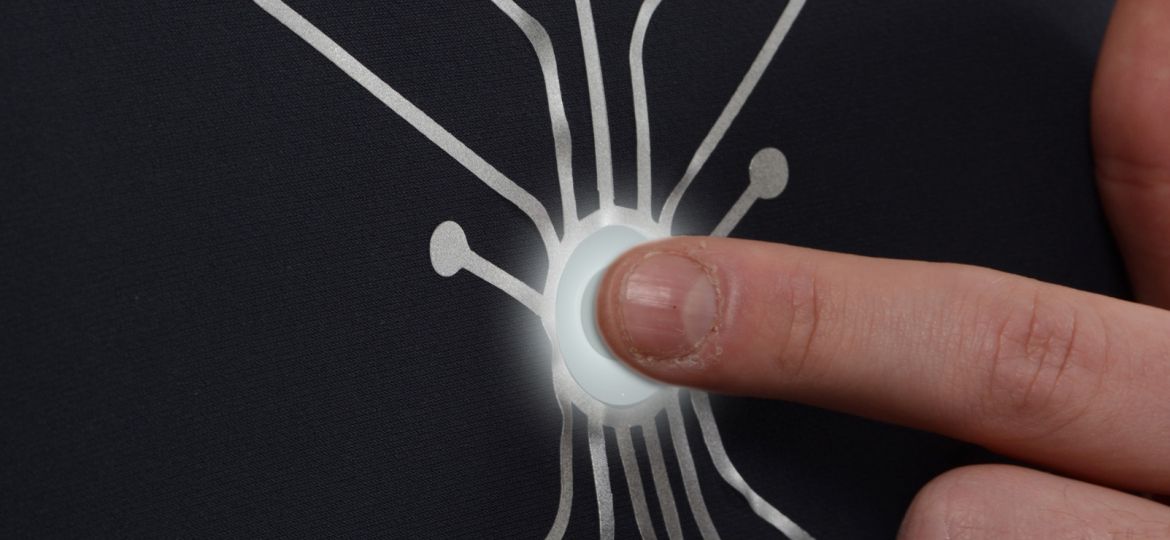

Fabric circuit demo reel, courtesy New Scientist

While the technology concept itself is novel and could indeed lead to a new proliferation of “Smart Clothing” some of the more interesting use cases for it could lie in the military sector.To demonstrate their circuits’ suitability for the military and security segment, developers Qiao Li and Xiao Ming Tao, fitted a sample under a layer of Kevlar and shot it several times with a .45 hand gun. The fabric continued to function so, as a consequence, the team believe it could be integrated into smart body armour, which could communicate when a wearer had been shot, providing the field commanders and medics with extra intel.