WHY THIS MATTERS IN BRIEF

Materials that don’t react to heat, or cold could make structures safer and solve one of the aerospace industry’s most troublesome issues.

Researchers at the University of Southern California have been trying to make a material that doesn’t respond to heat, and it seems they’re getting close and if they’re able to create this wonder material it could have big applications in aerospace, construction and engineering.

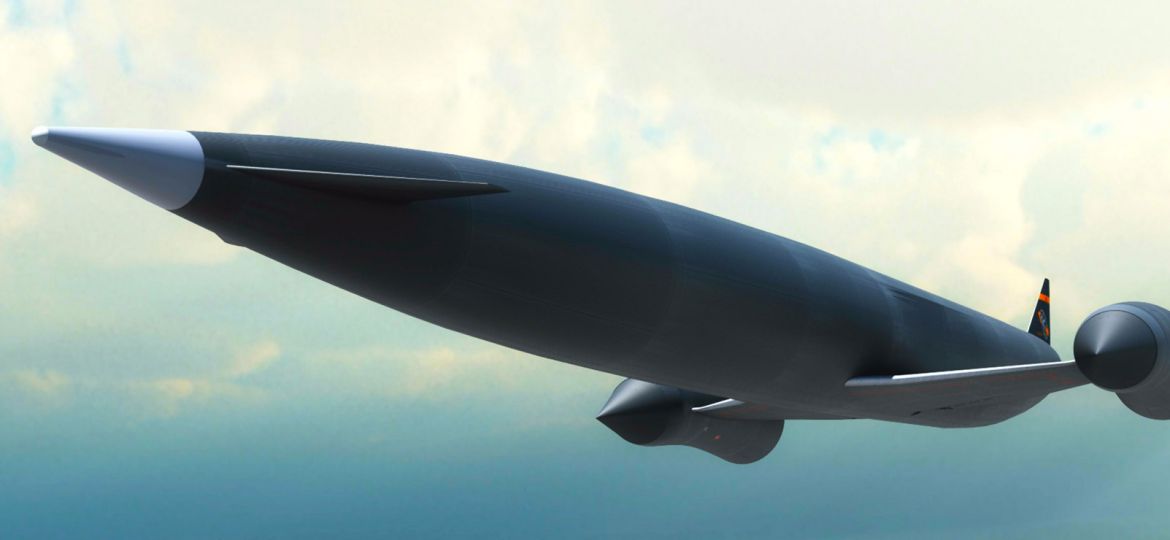

Most materials expand when they’re heated, which can be a huge engineering challenge. Large structures like bridges and buildings need to have expansion joints built in that allow the structure to expand safely without suffering damage, while at the same time companies like BAE, Boeing and Lockheed have to grapple with the laws of thermodynamics that, all too often, tear their newest hypersonic jets and gliders, such as the HTV-2 apart. When objects are made from two different materials that expand at different rates when heated, they can crack or shatter and that’s not a great scenario when you’re, for example, building skyscrapers or other large buildings.

So USC designed a manufacturing process where 3D printed structure can be made from several different materials. These materials are first printed as a liquid and solidified using UV light. Using this technique, the team printed an object with an internal lattice structure with several beams arranged at specific angles. The different materials that make up the object expand at different rates, and together the expansion pulls the beams inward.

The end result is that the object contracts, instead of expands, when heated. But by using different materials and different lattice arrangements, the team hopes to be able to customise the expansion and contraction rates, and even create a material that doesn’t expand at all, then, finally we might have material that can make our buildings and bridges safer and – more importantly we might be able to travel from London to San Francisco in 45 minutes.